Dredging For New Fish Habitats

Dredging is a necessary and beneficial practice that can create better ecosystems for fish. Unprecedented changes in our marine environment has led...

8 min read

U.S. Aqua Services Jan 13, 2026 4:04:32 PM

Dredging is a far more nuanced process than simply dragging a large bucket across the bottom of a river or body of water. Because no two projects are the same, there are many different types of dredgers, each designed with unique features to perform effectively in specific environments and material conditions.

In this blog post, we examine the eight most common types of dredgers, explain how they work, and outline where each one is most commonly used.

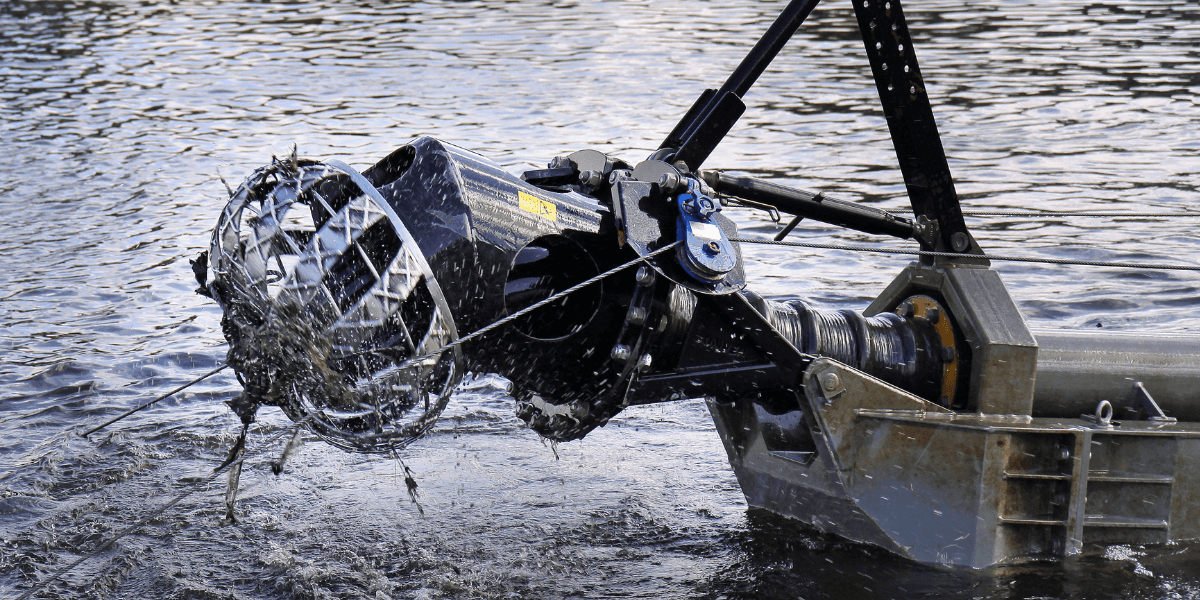

A Cutter Suction Dredger (CSD) is a stationary dredger that uses a rotating cutter head to loosen compact material before suctioning it through a pipeline.

One of the most enduring and versatile dredger designs, the Cutter Suction Dredger, employs a rotating cutter head at the end of a suction line. This cutter head is typically shaped like a basket and features blades that rotate within it. When the blades make contact with the seabed or riverbed material, they cut and loosen it, allowing the material to be drawn up into a suction tube.

From there, powerful pumps transport the dredged material into a housing or directly through a discharge pipeline to the designated disposal site. These disposal sites can be onshore for land reclamation, offshore for creating new landforms, or to a barge for further transport. High-capacity centrifugal pumps are often required to efficiently move the sediment-water mixture.

Cutter Suction Dredgers are highly adaptable, as they can be equipped with a variety of blades and scoops designed to handle different types of materials, ranging from soft silt and sand to hard clay and rock.

Common applications include:.png?width=450&height=300&name=blog%20internal%20images%20600x400%20(1).png)

Deepening navigation channels

Harbor and port maintenance

Underwater mining operations

Environmental remediation

Flood control and waterway capacity improvement

The precision and efficiency of cutter suction dredgers, combined with their ability to manage large volumes of material, make them indispensable in marine engineering and hydraulic projects.

A Trailing Suction Hopper Dredger (TSHD) is a self-propelled vessel designed to dredge loose seabed materials while moving.

A Trailing Suction Hopper Dredger is equipped with powerful suction pipes that extend to the seabed, making it one of the most efficient and widely used dredger types in the industry. These dredgers are designed to handle loose and soft materials such as sand, gravel, and silt.

The suction pipes, equipped with dragheads, are lowered to the seabed where they vacuum up the material and transport it into the vessel's hopper, a large storage compartment within the hull. Once the hopper is full, the vessel sails to the disposal site where the material is released through bottom doors or pumped out via pipelines..png?width=450&height=300&name=Red%20trailing%20suction%20hopper%20dredging%20boat%20roaring%20across%20the%20sea%2c%20by%20U.S%20Aqua%20(1).png)

TSHDs are among the most efficient and widely used dredger types due to their ability to operate continuously and in rough sea conditions.

Typical uses include:

Maintenance dredging of shipping channels

Port and harbor construction

An Excavator Dredger, also known as a Backhoe Dredger, removes material using a bucket mounted on a hydraulic excavator positioned on a barge.

For projects that demand the rapid movement of large quantities of material, an excavator dredger is the ideal solution. This type of dredger operates much like a land-based excavator, using a robust bucket fitted with a series of teeth or scrapers along one edge. These teeth are designed to break into and scoop up various materials, including compacted soil, sand, and even heavy rocks.

.png?width=450&height=300&name=a%20yellow%20back%20hoe%20dredger%20on%20a%20barge%20pulling%20sediment%20from%20a%20large%20body%20of%20water%2c%20provided%20by%20US%20Aqua%20(2).png) Excavator dredgers are particularly useful in confined or shallow areas where other types of dredgers may struggle to operate. They excel in precision dredging tasks, such as clearing dock basins, constructing and maintaining marina facilities, and performing underwater construction work. The ability to accurately position the bucket and apply significant force allows these dredgers to perform detailed and robust excavation tasks.

Excavator dredgers are particularly useful in confined or shallow areas where other types of dredgers may struggle to operate. They excel in precision dredging tasks, such as clearing dock basins, constructing and maintaining marina facilities, and performing underwater construction work. The ability to accurately position the bucket and apply significant force allows these dredgers to perform detailed and robust excavation tasks.

Additionally, their adaptability to various site conditions and material types makes them invaluable for a wide range of dredging projects. The mechanical nature of the excavation process ensures a consistent and controlled removal of material, which is crucial for maintaining the stability of underwater structures and ensuring navigable waterways.

A Grab Dredger, or Clamshell Dredger, uses a crane-mounted bucket to lift material vertically from the seabed.

The clamshell dredger or, grab dredger, operates with a distinctive bivalve grabbing system suspended from a crane, which is controlled either by cables or hydraulic cylinders. Resembling a giant mouth suspended from a long tether, this dredger methodically excavates materials from the bottom of water bodies.

Equipped with two hinged buckets resembling the halves of a clamshell, the dredger descends to the seabed or riverbed. The clamshell buckets are lowered open and then closed to grip and lift material, ensuring efficient excavation. This action is facilitated by the crane's lifting capacity, allowing the dredger to handle various sediment types, from loose sand to compacted clay and debris..png?width=450&height=300&name=An%20orange%20clamshell%20bucket%20dredger%20on%20a%20crane%20provided%20by%20US%20Aqua%20%20(1).png)

Clamshell dredgers are employed in a wide range of dredging applications, including harbor maintenance, construction projects, and environmental remediation.

Key advantages include:

High positional accuracy

Ability to handle debris and compact material

Controlled material placement

Grab dredgers ability to precisely target and remove specific volumes of material makes them particularly useful in shaping and maintaining navigational channels and berthing areas. The controlled deposition of dredged material onto barges or holding tanks ensures efficient transport and disposal, supporting sustainable dredging practices.

A Bucket Ladder Dredger uses a continuous chain of buckets to excavate material from the seabed.

Sand dredgers operate by lowering a series of buckets attached to a chain to the bottom of a river or water body. The buckets, equipped with sharp edges or teeth, scoop up the sediment, gravel, and other materials from the bottom as the chain system rotates.

.png?width=450&height=300&name=An%20old%20school%20dredging%20station%20in%20a%20small%20body%20of%20water%20in%20the%20middle%20of%20the%20mountains%20used%20for%20gold%20dredging.%20(1).png) Bucket ladder dredgers are especially advantageous for projects requiring the excavation of compacted or heavy materials. Their robust construction and powerful scooping action make them ideal for removing stubborn sediments, clay, and even large rocks from the seabed or riverbed. Sand dredgers are commonly used in harbor and port construction, canal maintenance, and mining operations where precise and efficient material removal is essential.

Bucket ladder dredgers are especially advantageous for projects requiring the excavation of compacted or heavy materials. Their robust construction and powerful scooping action make them ideal for removing stubborn sediments, clay, and even large rocks from the seabed or riverbed. Sand dredgers are commonly used in harbor and port construction, canal maintenance, and mining operations where precise and efficient material removal is essential.

One of the key benefits of bucket ladder dredgers is their ability to maintain a consistent and controlled dredging depth. This precision ensures that the dredged area is uniform, which is crucial for creating stable foundations for underwater structures and maintaining navigable waterways. Additionally, the continuous operation of the bucket ladder system minimizes downtime, increasing the overall efficiency of the dredging process.

A Suction Dredger removes loose material using hydraulic suction rather than mechanical digging.

When a project requires the removal of vast quantities of loose materials such as soil, silt, and fine gravel, suction dredgers are the ideal choice. These powerful machines utilize a hydraulic system to draw materials up through a specialized attachment, functioning much like a giant household vacuum cleaner. This efficiency and simplicity make suction dredgers indispensable in various dredging operations.

.png?width=450&height=300&name=a%20large%20boat%20with%20a%20suction%20dredger%20pulling%20sediment%20off%20of%20a%20work%20site%20with%20a%20yellow%20backhoe%2c%20rented%20from%20US%20Aqua%20%20(1).png) Suction dredgers operate by creating a vacuum that draws sediment and debris from the bottom of water bodies through a suction pipe. The hydraulic system generates the necessary force to lift the material from the seabed or riverbed and transport it to a designated holding area or directly onto a barge for removal. This process ensures the effective and rapid excavation of large volumes of material, making suction dredgers highly efficient for projects with loose sediments.

Suction dredgers operate by creating a vacuum that draws sediment and debris from the bottom of water bodies through a suction pipe. The hydraulic system generates the necessary force to lift the material from the seabed or riverbed and transport it to a designated holding area or directly onto a barge for removal. This process ensures the effective and rapid excavation of large volumes of material, making suction dredgers highly efficient for projects with loose sediments.

Additionally, suction dredgers are widely used in maintaining and deepening navigational channels, ensuring safe passage for vessels by removing silt and sediment buildup. They are also employed in land reclamation projects, where large volumes of sand and silt are required to create new landforms or restore eroded coastlines. The agricultural industry benefits from suction dredgers as well, utilizing them to clear irrigation channels and maintain water management systems.

Jet-Lift and Air-Lift dredgers are specialized systems designed for precise sediment removal using fluid dynamics. Jet-Lift dredgers use high-pressure water jets to create suction that lifts sediment into a pipeline. These systems are commonly used for maintenance dredging, beach nourishment, and environmental cleanup projects. Air-Lift dredgers inject compressed air into a submerged pipe, reducing density and allowing sediment to rise through buoyancy. These dredgers are ideal for underwater construction, scientific sampling, and salvage operations.

.png?width=450&height=300&name=A%20large%20boat%20in%20the%20middle%20of%20the%20ocean%2c%20using%20a%20jet%20lift%20dredger%20to%20move%20sediment%2c%20rented%20from%20US%20Aqua%20(1).png) Jet-Lift dredgers employ high-pressure water jets to create a suction effect that lifts sediment from the seabed or riverbed. The water jets are directed into a specially designed nozzle or intake pipe, generating a vacuum that draws in the sediment along with the water. This mixture is then transported through a pipeline to the desired disposal site or holding area.

Jet-Lift dredgers employ high-pressure water jets to create a suction effect that lifts sediment from the seabed or riverbed. The water jets are directed into a specially designed nozzle or intake pipe, generating a vacuum that draws in the sediment along with the water. This mixture is then transported through a pipeline to the desired disposal site or holding area.

Jet-Lift dredgers are commonly used in maintenance dredging of harbors, ports, and navigational channels where sediment accumulation can hinder vessel movement. They are also employed in beach nourishment projects, where large volumes of sand need to be relocated to restore eroded coastlines. Additionally, these dredgers are useful in environmental remediation efforts, such as removing contaminated sediments from water bodies to improve water quality.

.png?width=450&height=300&name=An%20air%20lift%20dredger%20moving%20sediment%20from%20a%20large%20body%20of%20water%20into%20a%20designated%20area%20established%20by%20US%20Aqua%20(1).png) Air-Lift dredgers operate on a different principle, using compressed air to lift and transport sediment. In this system, compressed air is injected into a submerged pipe, creating a flow of air bubbles that rise through the pipe. As these bubbles ascend, they reduce the density of the water-sediment mixture inside the pipe, causing the material to be lifted to the surface through buoyancy.

Air-Lift dredgers operate on a different principle, using compressed air to lift and transport sediment. In this system, compressed air is injected into a submerged pipe, creating a flow of air bubbles that rise through the pipe. As these bubbles ascend, they reduce the density of the water-sediment mixture inside the pipe, causing the material to be lifted to the surface through buoyancy.

Air-Lift dredgers are widely used in underwater construction projects, such as laying pipelines and cables, where precise sediment removal is necessary. They are also effective in scientific research operations, where sediment samples need to be collected from deep ocean floors without contamination. Furthermore, Air-Lift dredgers are valuable in salvage operations, helping to uncover and retrieve sunken objects or debris from the seabed.

Autonomous dredgers are unmanned systems controlled remotely or through advanced automation.

Remote or autonomous dredgers represent a cutting-edge innovation in the dredging industry, revolutionizing how underwater excavation and construction projects are managed. These unmanned machines are controlled by sophisticated computer systems, making them ideal for tasks that are environmentally sensitive or hazardous for human operators.

.png?width=450&height=300&name=A%20male%20worker%20in%20the%20control%20room%20of%20a%20large%20ship%2c%20giving%20instructions%20to%20workers%20using%20an%20autonomous%20dredger%20rented%20by%20U.S%20Aqua%20(1).png) Equipped with a suite of advanced attachments such as cameras, sonars, and sensors, autonomous dredgers operate autonomously while ensuring safe interaction with their surroundings. Autonomous dredging technologies enable them to accurately map the seabed or riverbed topography and identify specific materials that require removal. By leveraging real-time data and environmental feedback, autonomous dredgers optimize their operations for efficiency and precision.

Equipped with a suite of advanced attachments such as cameras, sonars, and sensors, autonomous dredgers operate autonomously while ensuring safe interaction with their surroundings. Autonomous dredging technologies enable them to accurately map the seabed or riverbed topography and identify specific materials that require removal. By leveraging real-time data and environmental feedback, autonomous dredgers optimize their operations for efficiency and precision.

The deployment of autonomous dredgers is particularly advantageous in the construction and maintenance of marine infrastructure, including port facilities and coastal defenses. These remote dredgers autonomously navigate through designated areas, performing dredging tasks without human intervention. This capability not only enhances operational flexibility but also extends operational hours, as autonomous dredgers can work continuously without the need for breaks or shift changes.

Choosing the right dredger depends on material type, water depth, project scale, and environmental conditions.

At U.S. Aqua Services, we simplify the selection process by offering a full range of dredge rentals and expert guidance. From small-scale pond maintenance to large sand dredging operations, our equipment is built for mobility, reliability, and safety.

Whether you need a cutter suction dredger, hopper dredger, or autonomous system, our team is ready to help you choose the right solution for your project. Contact us today to find out how we can assist with your next project!

The Importance Of Dredging - In this blog post, we will discuss the importance of dredging and some of its benefits.

Dredging For Environmental Remediation - This article will explain the importance of environmental dredging as well its benefits while discussing several different techniques used today.

5 Technological Advancements We're Excited to See More of in 2023 - Here are the top five technological advancements that will make waves in the dredging and construction industry in 2023.

U.S. Aqua Services was created to support the dredging process in advancing commerce and responding to its many challenges. To accomplish this, our dredging company assembled an exceptional group of experienced individuals and a diverse inventory of dredge equipment.

We offer dredging equipment rental services so you can have access to the latest and greatest in dredging technology without having to pay to maintain it, transport, and store it, along with dewatering services.

With an emphasis on mobility, dependability, durability, diversity, efficiency, and safety, our dredging rental company can ensure that our different types of dredging systems are easy to move through any terrain and can work in the most rugged and remote environments. Our multi-function hydraulic systems are built with jetting and mechanical options that can efficiently move loose sediment or stiff layers of clay.

US Aqua services also and maintains a ready fleet of amphibious equipment capable of completing dredging projects in some of the harshest and most remote environments. U.S Aqua is also the dealer for Louisiana of the amphibious vehicle Fat Truck. No matter the size or scope of the job or the remoteness of your work location, you can rely on Fat Truck’s industrial off-road utility vehicles to get the job done right.

Dredging is a necessary and beneficial practice that can create better ecosystems for fish. Unprecedented changes in our marine environment has led...

As most of us know, the act of dredging is when a dredge removes materials from the bed of a body of water and moves them to another place. That...

Dredgers are used to excavate various types of soil for a variety of purposes. Depending on the intended use of the dredged material, different...